Sunflower Seed hulling Equipment

- TFKH-1500

- China

- 7-20 days

- 30 sets

1. Sunflower seed hulling machine uses a wider seed kernel separation screen, which can improve the efficiency of sunflower seed separation and make the separated sunflower seeds more complete.

2. The intelligent electronic control system of sunflower seed sheller supports parameter adjustment and remote monitoring, and can control temperature, humidity, speed, wind power, etc.

3. Sunflower seed dehulling equipment adopts variable frequency design, which can adjust the frequency at any time according to the situation of sunflower seeds.

Introduction of Sunflower Seed Dehulling Machine:

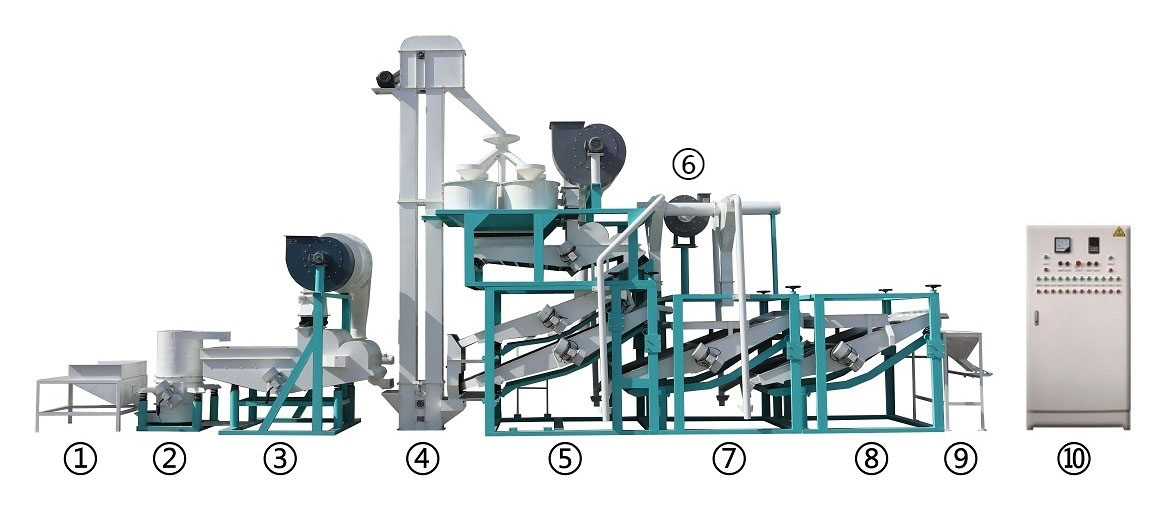

Our sunflower seed dehulling machine can complete the cleaning, shelling, shelling and kernel separation of sunflower seeds at one time, and can be widely used in the production of candy sunflower kernels and baked sunflower kernels. Sunflower seed hulling machine adopts multi-stage wind selection, precision speed adjustment roller pressing and automatic so,rting system, which can complete the shelling process efficiently. Sunflower seed hulling machine is mainly composed of feed hopper, spiral elevator, multifunctional cleaning machine, bucket elevator, equipment body (huller, air separator and kernel separator), return hopper, kernel re-selector 1, kernel re-selector 2, kernel bin and electrical control cabinet.

Features of sunflower seed dehulling equipment:

1. Sunflower seed dehulling machine adopts a unique multifunctional cleaner to ensure that the sunflower seeds entering the huller are pre-cleaned and various impurities can be effectively separated.

2. The hulling design of sunflower seed hulling equipment can effectively suck out all shells, and the content of sunflower kernels in the shells can reach up to 0.5%.

3. The 4 larger diameter hulling machine designs of sunflower seed hulling machine improve the hulling capacity, and the inverter is equipped with an electrical control cabinet, which can adjust the frequency according to the physical moisture of the raw sunflower seeds.

Purpose of sunflower seed dehulling equipment:

Sunflower seed sheller can separate the shell and kernel of whole sunflower seeds, and the produced sunflower seed kernels are more complete and clean. Therefore, our sunflower seed sheller can be used for the production and processing of baked foods such as bread and biscuits. It is also suitable for the production of candy sunflower seed kernels. The sunflower kernels produced by our sunflower seed hulling machine also better meet the requirements of foreign customers for food-grade raw materials.

Technical Parameters of Sunflower Seed hulling Equipment:

| Power of Sunflower Seed sheller | 20.24 kw (380v) |

| Input capacity of Sunflower Seed hulling Equipment | 0.8-1.25 mt/h |

| % of whole kernels (broken kernel less than 1/2 of whole one) | 90% min. |

| % of inshell in kernels | 5% max. |

| Overall dimension (L*W*H) | 13.1 x 2.92 x 5.4m |

How to use sunflower seed sheller?

Before using sunflower seed sheller, we must carefully read the product manual and be familiar with the operation process. Then pour the raw sunflower seeds into the feeding system of sunflower seed dehulling equipment for preliminary screening. Then the pre-treated sunflower seeds are evenly fed into the shelling machine through the speed-adjusting conveyor belt of sunflower seed dehulling machine. The mixture of shelled kernels, shells, and unshelled seeds will enter the sorting area through the winnowing machine for automatic separation.

The whole kernels of sunflower seed hulling equipment will be transported to the subsequent processes such as dryer, frying machine or packaging machine through the conveyor line. The whole seeds that have not been removed can automatically flow back to the shelling machine for further processing.

About us:

Liaoning Qiaopai Machinery Co., Ltd. is an enterprise specializing in the production and design of complete processing production lines for cleaning, shelling, grading and selecting grain and oil crops. Qiaopai Machinery's products mainly include more than 40 complete processing production lines for agricultural and sideline products, covering the cleaning, grading, lifting, shelling and selecting of crops such as sunflower seeds, buckwheat, oats, flax seeds and almonds.