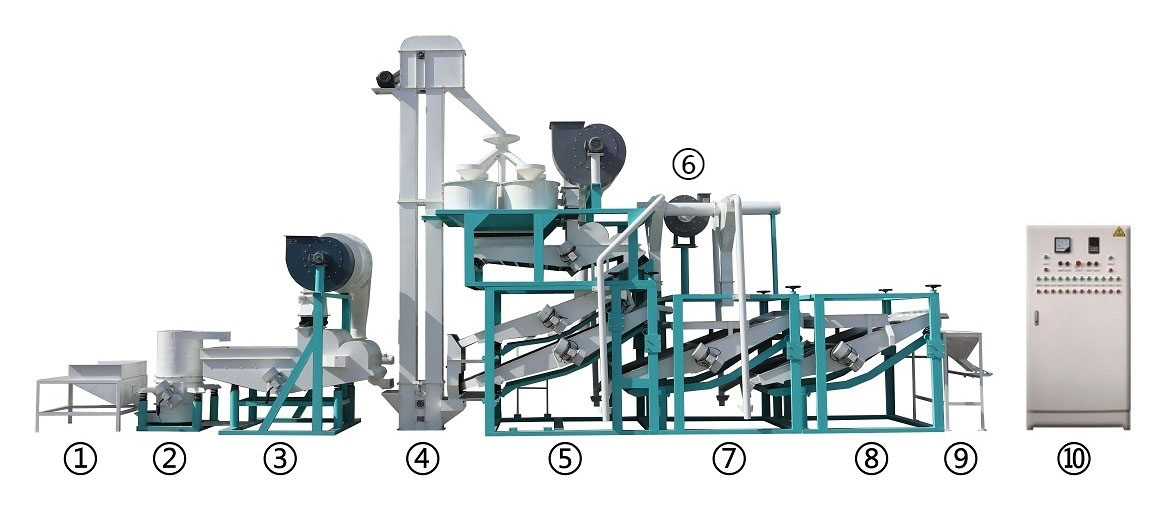

Sunflower Seed huller

- TFKH-1500

- China

- 7-20 days

- 30 sets

1. The sunflower seed dehulling machine has low energy consumption, low operating noise, and no oil splashing during operation, which can ensure the cleanliness of the production environment.

2. The sunflower seed hulling equipment is easy to disassemble, clean and maintain, and meets the requirements of the food industry for hygiene standards.

3. The sunflower seed hulling machine can flexibly adjust the spacing according to different sunflower seed varieties. Sunflower seed dehulling machine can be used for the production of a variety of sunflower seeds.

Introduction to sunflower seed huller:

Sunflower seed dehulling equipment is an integrated equipment that can realize shelling, screening, wind selection and automatic recycling, and can be widely used in industries such as deep processing of sunflower seed food. Our sunflower seed dehulling machine is scientifically designed to continuously and stably load, shell and screen, and can adapt to sunflower seed raw materials of different sizes and water contents. Sunflower seed hulling equipment is made of high-quality raw materials, with a solid structure and strong wear resistance, which meets food safety requirements.

Features of sunflower seed hulling machine:

1. Sunflower seed huller adopts independent shelling system and wind separation system to ensure that the shelling rate of sunflower seeds is above 90% and the integrity of sunflower seeds is good. And it can also flexibly adjust the spacing according to different sunflower seed varieties, effectively adapt to a variety of raw materials with thin shells and tender kernels or thick shells and small kernels, and improve adaptability.

2. Sunflower seed dehulling equipment adopts intelligent vibrating screen and wind separation fan, which can effectively remove impurities and unshelled seeds to ensure that the finished sunflower seed kernels are clean and free of impurities.

3. Sunflower seed dehulling machine is equipped with plc automatic control system, which can realize automatic start and stop, blockage detection, fault alarm and other functions. Sunflower seed hulling equipment can not only reduce the pressure of manual operation, but also improve the safety and maintenance convenience of sunflower seed hulling equipment.

Use of sunflower seed hulling machine:

Sunflower seed huller can be used in the production of fried sunflower kernels, sunflower kernel sugar, baking ingredients and other snack production industries. Sunflower kernels produced by sunflower seed dehulling equipment can also be used in grain mixed food applications.

Technical parameters of sunflower seed hulling machine:

| Power of sunflower seed huller | 20.24 kw (380v) |

| Input capacity of sunflower seed huller | 0.8-1.25 mt/h |

% of whole kernels (broken kernel less than 1/2 of whole one) | 90% min. |

| % of inshell in kernels | 5% max. |

| Overall Dimension of sunflower seed huller(L*W*H) | 13.1 x 2.92 x 5.4m |

Precautions for using sunflower seed dehulling machine:

1. Before using sunflower seed hulling equipment, try to control the moisture content of sunflower seeds within an appropriate range. When starting the sunflower seed hulling machine, start the winnowing machine, vibrating screen, and shelling host in sequence, and do not start under load. When shutting down, the machine should also be shut down in sequence to avoid damage to the transmission parts.

2. After the sunflower seed huller has been running for a period of time, check whether each component is damaged in time. It is recommended to perform comprehensive maintenance once a month, including cleaning the electrical control box, replacing grease, and checking the line connectors.

3. Sunflower seed dehulling equipment should be placed in a dry and ventilated workshop to avoid humid environment that will corrode and damage various system components. If it is not used for a long time, clean the interior and disconnect the power supply. It is best to cover the surface with a layer of dustproof cloth.

About us:

Liaoning Qiaopai Machinery Co., Ltd. has a high-quality R&D team, which combines independent R&D advantages with talent advantages. Over the years, it has obtained more than 150 national patents. We have a professional after-sales service team that travels around the world all year round to provide customers with the most reliable and efficient technical support and professional installation and on-site commissioning services.