Pumpkin Seeds Shelling machine

- TFBGZ-300

- China

- 7-20 days

- 30 sets

1.Pumpkin seeds machine has passed iso9001:2015 and ce certification.

2.Pumpkin seeds shelling machine adopts wet shelling to humidify and soften pumpkin seeds, and the whole kernel rate can reach more than 90%.

3.The structure of pumpkin seeds machine is compact, which can effectively reduce the loss of pumpkin seeds during processing and improve the utilization rate.

Introduction of pumpkin seed huller:

Pumpkin seed dehuller is an efficient shelling equipment designed for pumpkin seeds and gourd seeds, zucchini seeds, watermelon seeds and other related species. Pumpkin seeds machine can be widely used in grain, nut processing enterprises, agricultural and sideline products deep processing plants and other industries. Pumpkin seeds shelling equipment can achieve high shelling rate and low kernel shell residue rate through scientific configuration of shelling parameters and efficient separation system.

Features of pumpkin seeds shelling machine:

1. Our pumpkin seed huller adopts a unique shelling design, which can effectively suck out all the shells, and the kernel content in the shell can reach up to 0.5%.

2. The pumpkin seed dehuller we produce is also suitable for shelling seeds with a similar structure to pumpkin seeds, and can meet the shelling needs of different types of products by replacing the grading screen.

3. Pumpkin seeds shelling equipment can adjust the inverter of the shelling machine to accurately control the shelling according to the humidity, particle size and shell thickness of the pumpkin seeds, effectively avoid pumpkin seed damage, and improve the shelling quality of pumpkin seeds.

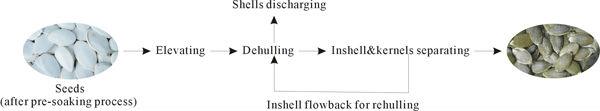

Process flow of pumpkin seed dehuller:

The entire process of the pumpkin seeds machine can be divided into feeding - lifting - shelling - shelling kernel separation - pumpkin seeds. Pour the raw pumpkin seeds into the feeding hopper of the pumpkin seeds shelling equipment, and transport the raw materials to the multi-functional cleaning equipment through the spiral elevator to separate and remove large, light, heavy and other impurities. The cleaned pumpkin seeds are sent to the grading equipment through the bucket elevator of the pumpkin seeds shelling machine, and the pumpkin seeds of different grades are sent to the shelling unit of the pumpkin seed dehuller respectively, and precise shelling is carried out under the set humidity and shelling parameters. During the shelling process, the high-speed shelling system in the pumpkin seed dehuller and the high-efficiency air separator work together to quickly separate the shell from the kernel.

Composition of pumpkin seeds shelling equipment:

The entire process of the pumpkin seeds machine can be divided into feeding - lifting - shelling - shelling kernel separation - pumpkin seeds. Pour the raw pumpkin seeds into the feeding hopper of the pumpkin seeds shelling equipment, and transport the raw materials to the multi-functional cleaning equipment through the spiral elevator to separate and remove large, light, heavy and other impurities. The cleaned pumpkin seeds are sent to the grading equipment through the bucket elevator of the pumpkin seeds shelling machine, and the pumpkin seeds of different grades are sent to the shelling unit of the pumpkin seed dehuller respectively, and precise shelling is carried out under the set humidity and shelling parameters. During the shelling process, the high-speed shelling system in the pumpkin seed dehuller and the high-efficiency air separator work together to quickly separate the shell from the kernel.

Technical Parameters of pumpkin seed huller:

Power of Pumpkin Seeds Machine | 8.54 kw (380V) |

Capacity of Pumpkin Seeds Shelling Machine | 200-300 kg/h |

% of inshell in kernels | 5% max |

% of whole kernels | 90% min |

| Overall Dimension (L*W*H) | 5.7 x 2.9 x 4 m |

FAQ:

1. What is the shelling rate of the pumpkin seeds machine?

Our pumpkin seed huller has a standard shelling rate of more than 95%.

2. Will the unshelled seeds in the pumpkin seed huller be wasted?

The pumpkin seed huller will perform secondary processing on the pumpkin seeds that are not completely shelled.

3. Is the pumpkin seed huller easy to clean?

Our pumpkin seed huller is relatively easy to clean.

About us:

Liaoning Qiaopai Machinery Co., Ltd. is a professional company integrating design, R&D and manufacturing, engaged in the production of complete sets of equipment for removing impurities, shelling, screening and grading grains, oilseeds and nuts. At present, it can provide processing equipment solutions for more than 40 raw materials such as sunflower seeds, buckwheat, oats, flax seeds, apricot kernels, etc..