Oat shelling equipment

- TFYM-1000

- China

- 7-20 days

- 30 sets

1. The grain dehuller can complete the processes of shelling, shelling, and kernel separation of oats.

2. The whole kernel rate of the grain huller is above 95%, with less kernel loss and easier maintenance.

3. The oat dehuller adopts a double shelling machine structure. Oat dehuller can not only improve the shelling efficiency, but also enable large-scale production. Grain dehuller is suitable for the production of medium and large enterprises.

Introduction of oat dehuller:

Our oat dehuller is an automated equipment specially used to process oats.And oat shelling machine retain the integrity of oat kernels to the greatest extent and reduce the loss of oats. Therefore, our oat shelling machine can be applied to enterprises that process oats. Moreover, our oat inpact huller meets food safety standards and can be used with confidence. The grain huller is made of high quality materials. And oat dehuller meets food grade standards.

Features of oat inpact huller:

1. The grain dehuller is integrated with advanced technical concepts. Grain huller is not only highly efficient, low energy consumption, but also occupies a relatively small area.

2. The oat shelling machine adopts a double shelling machine structure. Oat inpact huller can improve the processing efficiency by at least 20%.

3. The oat inpact huller is equipped with an intelligent frequency converter. Oat inpact huller adjusts the shelling frequency according to the physical properties of different oat raw materials, so that it can be used for oats with different moisture ratios.

The purpose of oat inpact huller:

Our oat shelling equipment is mainly used for the pretreatment process of oat raw materials. Grain dehuller is suitable for food processing enterprises, grain deep processing plants, health food production lines and agricultural cooperatives. Grain dehuller can separate oat kernels more completely and efficiently. The grain huller we produce can also be used in the front-end processing of instant oatmeal powder, oat flakes, cereal nutrition bars, meal replacement powder and other products. Oat dehuller can meet the requirements of european and american markets for the purity, completeness and safety and hygiene of oat kernels.

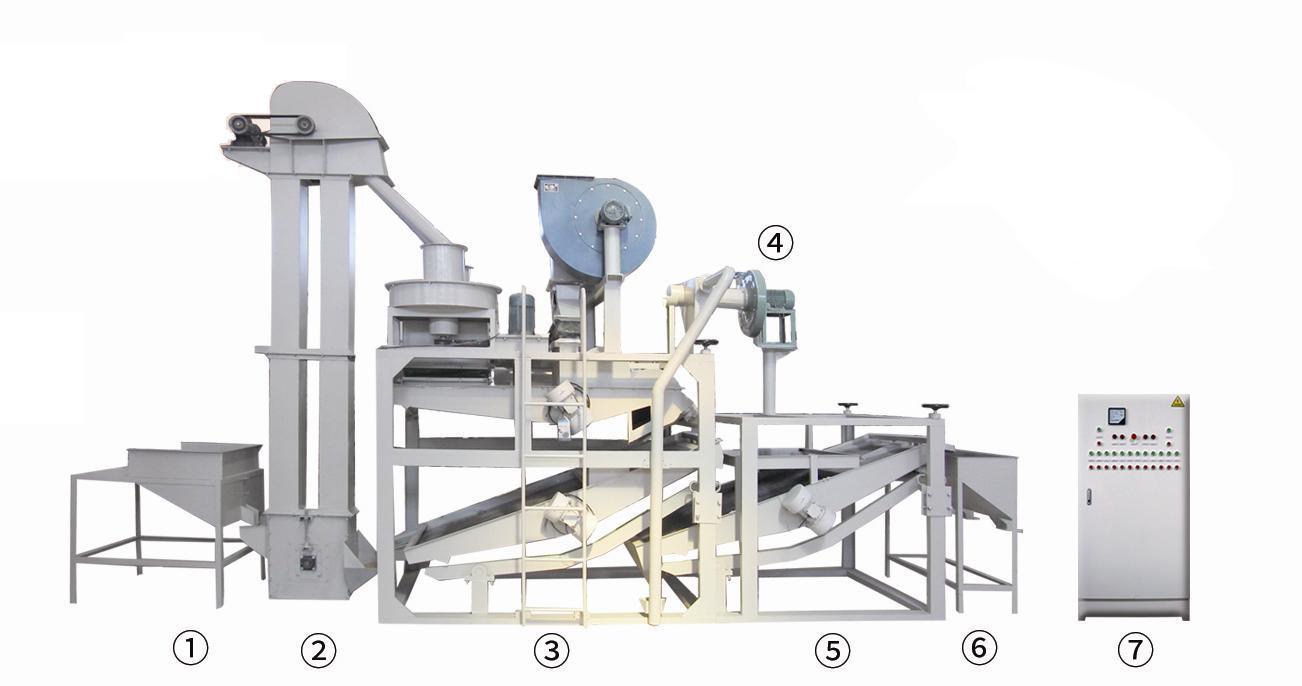

Composition of grain dehuller:

The grain dehuller consists of 7 parts: Feed hopper, bucket elevator, equipment body, reflux gas system, kernel re-separator, kernel bin, and electrical control cabinet. The various parts cooperate with each other, and the oat kernels produced have a high integrity rate. Grain dehuller effectively avoids the waste of oat raw materials.

Technical Parameters of oat dehuller:

| Power of oat dehuller | 10.48-11.2 kw (380V) |

| Input capacity of oat dehuller | 0.8-1.0 mt/h |

| % of Whole Kernel | 95% min. |

| % of Inshell in Kernels | 2% max. |

| % of Brokens in Shells | 0.5% max. |

| Overall dimension of oat dehuller (L*W*H) | 7.6 x 2.8 x 4.4m |

How to use the oat shelling machine:

Oat shelling machine will enter working mode after being powered on. Use the oat shelling machine touch screen to set parameters such as shelling speed, wind separation intensity, vibration frequency, etc. Then pour the oats into the hopper of the oat inpact huller and start shelling. The oats will move at high speed in the drum of the grain dehuller for automatic separation. The oat kernels will pass through the outlet of the grain huller.

Maintenance of oat dehuller:

After long-term use, the air duct of the oat shelling machine May be blocked due to dust accumulation. After use, check whether the air duct of the oat inpact huller is smooth. And clean grain huller regularly. It is also necessary to check the use of the air filter cloth of grain huller every week. If it is damaged, seriously contaminated or deformed, it should be replaced in time. Regularly check the high-speed rotating parts such as the main shaft of grain huller, motor belt of grain huller, bearings of grain huller, etc., and pay attention to the amount of lubricating oil used. For damaged parts of grain huller, we must replace them in time to ensure that the grain dehuller can work normally.

About us:

Liaoning Qiaopai Machinery Co., Ltd. is a company specializing in the production and design of complete processing production lines for grain and oil crops cleaning, shelling, grading, and selection. The products mainly include more than 40 complete processing production lines for agricultural and sideline products.