Oat dehulling machine

- TFYM-1000

- China

- 7-20 days

- 30 sets

1. Grain huller combines multi-stage wind selection channels with gravity grading systems to achieve efficient separation of oat seed hulls, and the residual amount of oat kernels is about 0.5%.

2. Oat dehuller adopts a unique shelling and wind selection system. Oat dehuller is simple to maintain. And grain huller has stable performance. And oat dehuller can ensure processing accuracy.

3. The oat shelling machine adopts a modular design, and the installation is relatively simple during actual operation. Just follow the instructions.

Introduction of oat dehuller:

Oat shelling machine is an efficient equipment specially used for shelling oats. Oat inpact huller adopts double shelling equipment. Oat dehuller can quickly complete the shelling of oats. Our grain dehuller can also integrate the three tasks of shelling, air separation and kernel separation. And our grain huller has passed ISO9001:2015 quality management system certification and eu ce certification. Oat dehuller can guarantee the quality of products.

Features of oat dehuller:

1. Our oat shelling machine can adjust the shelling frequency according to the physical properties of different oats. Oat dehuller can meet the needs of different batches of oats with large changes in moisture content. And oat dehuller ensure the dual optimization of shelling rate and whole grain rate.

2. Oat inpact huller includes complete processing units such as feed hopper, bucket elevator, sheller, air separator, kernel separator, reflux gas system, re-separator and finished product warehouse. Oat shelling machine can realize automatic closed-loop processing from loading to discharging.

3. Our grain dehuller also adopts a low-noise structure design. Oat shelling machine is relatively stable during operation. And oat inpact huller can reduce interference with the production environment.

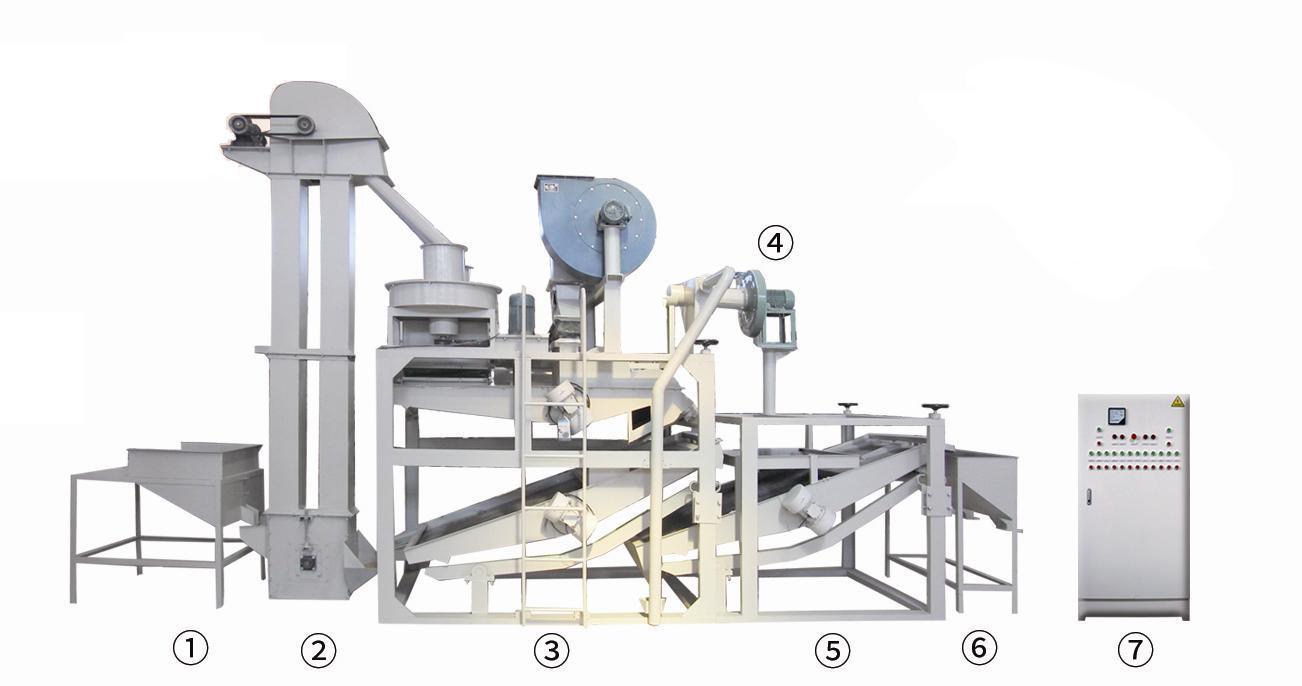

Component of oat inpact huller:

①input hopper of oat inpact huller②bucket elevator of oat inpact huller ③main part of the equipment(dehullers, air separator and seed-kernel separator) ④pneumatic system of back-flowing materials ⑤seed-kernel reseparator of oat shelling machine ⑥kernels bin of grain huller⑦electrical control cabinet of grain dehuller.

Technical parameters of grain dehuller:

| Power of grain dehuller | 10.48-11.2 kw (380V) |

| Input Capacity of grain dehuller | 0.8-1.0 mt/h |

| % of Whole Kernel of grain dehuller | 95% min. |

| % of Inshell in Kernels of grain dehuller | 2% max. |

| % of Brokens in Shells of grain huller | 0.5% max. |

| Overall Dimension (L*W*H) of grain huller | 7.6 x 2.8 x 4.4m |

Uses of oat inpact huller:

Grain dehuller can be mainly used in the production of healthy foods such as oat flour, oat flakes, cereal energy bars, and plant milk. Grain huller can retain oat kernels to the greatest extent. And grain huller improve the taste of the product. Many export-oriented companies can use oat dehuller to perform primary processing of oats.

How to use oat dehuller?

The use of oat shelling machine is very simple. Before using the oat inpact huller, we should preliminarily screen the oats to remove impurities. After starting the grain dehuller, the operator should set the parameters such as the shelling speed. In the daily use of the grain huller, we should check whether the bucket elevator can operate normally every day, observe whether the oat dehuller's air selection pipeline is unobstructed, regularly clean the sediment and dust in the separator. And grain huller do a good job of basic cleaning.

How to clean the oat shelling machine:

Because most of the parts of the oat inpact huller are designed with a quick-release structure, the cleaning process is relatively simple. We can choose a food-grade air pump or a vacuum cleaner to remove the internal dust of the grain dehuller. After cleaning, wipe the surface with a dry cloth to avoid moisture residue. The grain huller should be added to the moving parts after running for a period of time. Lubricating oil should be added to the moving parts once every 100 hours of operation to ensure that it can run for a long time.

About us:

Liaoning Qiaopai Machineries Co., Ltd. is a high-tech enterprise specializing in the research and development and manufacturing of complete processing production lines for grain and oil crops cleaning, shelling, grading and selection. Since its establishment more than 30 years ago, Qiaopai Machinery has always focused on independent innovation.