Oat dehullers

- TFYM-1000

- China

- 7-20 days

- 30 sets

1. The oat peeling machine has passed iso9001:2015 quality management system certification and CE certification. So oat huller complies with the food machinery safety standards of the EU and other international markets.

2. The oat processing equipment is equipped with a frequency converter and an intelligent electric control cabinet. Oat huller can adjust the shelling frequency according to the moisture content of the raw oats to achieve the best shelling effect and reduce breakage and loss.

3. The oat peeler machine adopts a scientific layout, so it occupies a small area. The oat peeling machine also uses energy-saving motors and reasonable transmission systems to reduce energy consumption during operation.

Introduction of oat peeler machine:

The oat peeler is a shelling machine used to process oats. The oat peeling machine has a high integrity rate of oat kernels and low oat loss. The oat processing equipment adopts an advanced double shelling machine structure design. And oat peeling machine is equipped with a frequency converter and an electric control cabinet. Our oat peeling machine can adjust the frequency according to the physical moisture content of the oats.

Features of oat huller:

1. The oat peeler machine can completely suck out the oat hull, and the content of residual kernels in the hull is controlled within about 0.5%. Oat peeler machine effectively reduces the loss of raw materials and improves the product recovery rate.

2. The oat dehullers have a compact structure, small footprint, stable operation, and our oat huller can be flexibly arranged in small and medium-sized factories.

3. The oat peeler machine adopts a double sheller structure. Our oat huller effectively improves the shelling capacity of the equipment and can improve the processing efficiency by more than 20%.

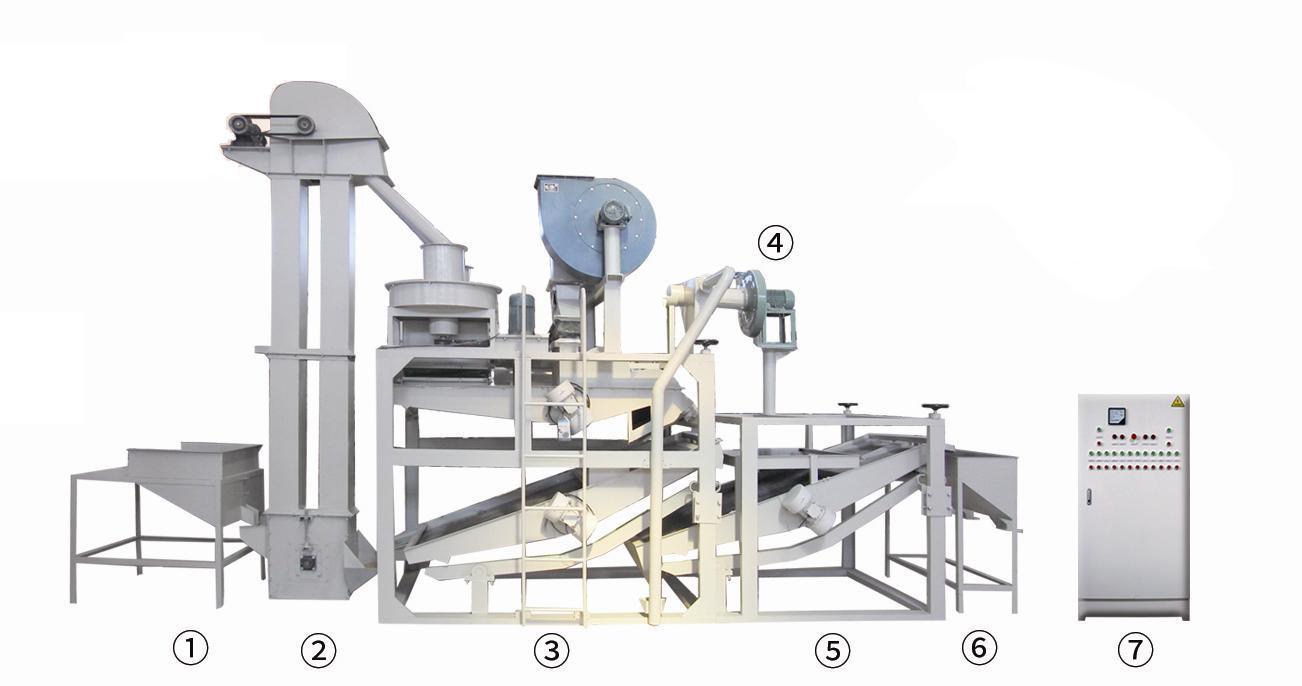

Composition of oat peeling machine:

Oat processing equipment consists of a feed hopper, a bucket elevator, the main body of the equipment (sheller, air separator and kernel separator), a reflux gas system, a kernel re-separator, a kernel bin, and an electrical control cabinet. Oats will first enter the system through the feed hopper of the oat huller, and then the bucket elevator will stably lift the oats to the feed port. The oats will be screened in turn by the three units of sheller, air separator and kernel separator. The screened gas and residue will be centrally processed by the reflux gas system to screen out clean and complete oat kernels.

Technical Parameter of oat peeler machine:

Power of oat peeler machine | 10.48-11.2 kw (380v) |

Input capacity of oat peeler | 0.8-1.0 mt/h |

% of whole kernels (broken kernel less than 1/2 of whole one) | 95% min. |

% of inshell in kernels | 2% max. |

% of Brokens in Shells | 0.5% max. |

Overall Dimension oat processing equipment (L*W*H) | 7.6x 2.8 x 4.4m |

Precautions for the use of oat peeling machine:

1. Before operating the oat processing equipment, check whether all mechanical connections are tight, check whether the power supply voltage is normal, and whether the electronic control system can start smoothly.

2. Before processing, pre-screen the oats to remove stones, metals and impurities to avoid damaging the oat peeler. It is also necessary to adjust the shelling frequency of the oat peeler electronic control system in time to retain the integrity of the oat kernel to the greatest extent.

3. In the daily use of the oat peeler, we must regularly clean the air duct and separator, and all transmission parts must be regularly filled with lubricating oil, and perform correct maintenance according to the operating manual.

Working principle of oat peeler:

The oat peeler machine mainly uses physical mechanics to separate oat seeds. The oat peeler machine separates oat kernels by mechanical impact, friction or extrusion, and completely separates oat kernels by combining wind selection and screening systems. Before entering the oat peeling machine, the oats must first be treated with foreign matter such as impurities on the surface. Then the oats are sent to the silo of the oat processing equipment. The oat kernels in the oat huller are subjected to physical methods such as centrifugal force, causing the shells to fall off automatically. The oat kernels are separated by weight. The unpeeled oats will enter the oat huller again for processing.

FAQ:

1. What types of oats are suitable for oat huller?

Oat huller is suitable for many types of oats.

2. What is the capacity of oat huller?

The capacity of oat huller is 0.8-1.0 mt/h.

3. Is the operation of oat huller stable?

Our oat huller operates stably and is environmentally friendly.

4. Is the operation of oat huller complicated?

We will provide the instruction manual of oat processing equipment and professional after-sales personnel will serve you.

About us:

Liaoning Qiaopai Machinery Co., Ltd. was established in 1992 and has always been committed to independent innovation and has a full set of patented technology products with independent intellectual property rights.