shelling machine

-

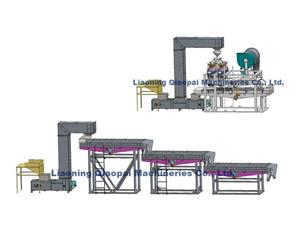

Oat Dehulling and Separating Equipment

01. This equipment is the optimum pretreatment equipment for oat meals production. 02. Twin-dehullers design increases dehulling capacity, with frequency inverter equipped with electric control cabinet to adjust the frequency according to physical moisture of the raw oats. 03.Unique shells-removing design makes all the shells aspirated properly, % of kernels in shells is 0.5% max. 04. ISO 9001 : 2015 & CE certified.

Email Details -

Buckwheat Seed Dehulling and Separating Equipment

1. Buckwheat peeling machine is made of high-quality materials, which is relatively wear-resistant and suitable for long-term processing of buckwheat. 2. Buckwheat peeling machine has a compact structure and occupies a small area. 3. Buckwheat peeling machine can efficiently complete the shelling work while ensuring the integrity of buckwheat kernels.

Buckwheat Shelling Dehulling Machine Buckwheat Dehulling and Separating Machine buckwheat peelling machine dehulling machineEmail Details -

Almond inshell Processing Equipment

1. The shelling rate of almond shelling machine is above 98%, which is more suitable for nuts with hard shell and crisp kernel. 2. The modular design of almond shelling machine makes it easy to disassemble the grading, shelling and sorting units, and the daily cleaning and maintenance are simple. 3. The almond shelling machine can provide international warranty and technical support services, and there is a dedicated after-sales team to serve you.

Hazelnuts Processing Equipment Badam Processing Equipment almond shelling machine almond cracking and shelling machineEmail Details -

Pakistani Pine Nut Dehulling and Separating Equipment

1. Pine nuts dehulling machine uses energy-efficient motors to reduce energy consumption and save operating costs. 2. The modular design of pine nuts peeling machine makes its operation and maintenance process easier. 3. Pine nuts separating is made of high-quality materials, with a solid structure and durable.

Pine Nuts Dehulling Machine Pine Nuts Peeling Machine Pine Nuts Hulling Machine pine nuts separatingEmail Details -

Pistachio Processing Equipment

1. Pistachio nuts sheller can separate pistachio kernels relatively completely, with a whole kernel rate of more than 95%, effectively reducing the waste of pistachio raw materials. 2. Large pistachio nuts sheller is equipped with a multi-level grading and screening mechanism, which can be adjusted according to the specifications of pistachios, improving the accuracy of the overall work. 3. Pistachio dehuller has also passed ISO9001:2015 international quality management system certification and EU CE safety certification, product quality is guaranteed, you can use it with confidence.

Email Details -

Job's Tear Dehulling and Separating Equipment

1. Job's Tear dehuller has passed iso9001:2015 quality management system certification and eu ce safety certification, and product quality is guaranteed. 2. Job's tears milling has a compact structure and small footprint, which can save production space. 3. The price setting of job's tears huller is reasonable and suitable for most coix seed shelling manufacturers.

Email Details -

Safflower Seeds Dehulling and Separating Equipment

1. High efficient 2. ISO9001:2015 and CE certified 3. International warranty and technical support 4. Competitive price

Email Details -

Oat shelling machine

01. This equipment is the optimum pretreatment equipment for oat meals production. 02. Twin-dehullers design increases dehulling capacity, with frequency inverter equipped with electric control cabinet to adjust the frequency according to physical moisture of the raw oats 03. Unique shells-removing design makes all the shells aspirated properly, % of kernels in shells is 0.5% max. 04. ISO 9001:2015 & CE certified

Email Details -

Oat dehuller

01. This equipment is the optimum pretreatment equipment for oat meals production. 02. Twin-dehullers design increases dehulling capacity, with frequency inverter equipped with electric control cabinet to adjust the frequency according to physical moisture of the raw oats 03.Unique shells-removing design makes all the shells aspirated properly, % of kernels in shells is 0.5% max. 04. ISO9001 : 2015 & CE certified

Email Details