separating

-

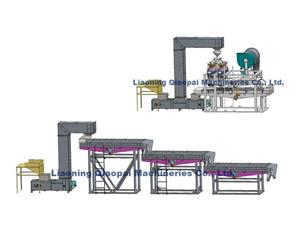

Buckwheat Seed Dehulling and Separating Equipment

1. Buckwheat peeling machine is made of high-quality materials, which is relatively wear-resistant and suitable for long-term processing of buckwheat. 2. Buckwheat peeling machine has a compact structure and occupies a small area. 3. Buckwheat peeling machine can efficiently complete the shelling work while ensuring the integrity of buckwheat kernels.

Buckwheat Shelling Dehulling Machine Buckwheat Dehulling and Separating Machine buckwheat peelling machine dehulling machineEmail Details -

Pakistani Pine Nut Dehulling and Separating Equipment

1. Pine nuts dehulling machine uses energy-efficient motors to reduce energy consumption and save operating costs. 2. The modular design of pine nuts peeling machine makes its operation and maintenance process easier. 3. Pine nuts separating is made of high-quality materials, with a solid structure and durable.

Pine Nuts Dehulling Machine Pine Nuts Peeling Machine Pine Nuts Hulling Machine pine nuts separatingEmail Details -

Cedar Pine Nuts Processing Equipment

1. High efficient 2. ISO9001:2015 and CE certified 3. International warranty and technical support 4. Competitive price

Email Details -

Hazelnuts sheller

1. High efficient 2. ISO9001:2015 and CE certified 3. International warranty and technical support 4. Competitive price

Email Details -

Sunflower seed dehulling machine

1. Sunflower seeds shelling machine has passed ISO9001:2015 and CE certification, and the quality of sunflower seed kernels meets the requirements for food use. 2. The sunflower seed impact huller has a compact structure, occupies a small space, and can effectively reduce the damage to the sunflower seed kernels. 3. Sunflower seeds dehulling and separating machine adopts automatic feeding, which makes operation and maintenance simpler.

Sunflower Seeds Dehulling and Separating Machine Sunflower Seeds Hulling Equipment Sunflower Seeds Dehulling Machine Sunflower Seeds shelling machineEmail Details -

Oat sheller

01. This equipment is the optimum pretreatment equipment for oat meals production. 02. Twin-dehullers design increases dehulling capacity, with frequency inverter equipped with electric control cabinet to adjust the frequency according to physical moisture of the raw oats 03.Unique shells-removing design makes all the shells aspirated properly, % of kernels in shells is 0.5% max. 04. ISO9001:2015&CE certified

Email Details -

Buckwheat Seed Dehulling Equipment

01. Dry method for dehulling. This equipment is used for both heat-treated buckwheats and non heat-treated buckwheat dehulling. 02.Unique shells-removing design makes all the shells aspirated properly, % of kernels in shells is 0.5% max. 03. High integrity of the shells/husks. 04. ISO 9001 : 2015 & CE certified.

buckwheat seed Equipment Buckwheat Seed Dehulling Buckwheat Seed Separating Buckwheat Seed Hulling EquipmentEmail Details -

Almond inshell shellers

1. The shelling rate of hazelnuts dehuller in actual operation is as high as 98%, and the whole kernel rate exceeds 90%, which is more efficient than general shelling equipment. 2. Separating shellers also have a relatively complete after-sales service system. Hazelnuts shellers can respond quickly and promptly when encountering problems. 3. The price of hazelnuts shellers is more favorable, cost-effective, and suitable for small and medium-sized processing enterprises.

Email Details -

Almond inshell cracking machine

1. High efficient 2. ISO9001:2015 and CE certified 3. International warranty and technical support 4. Competitive price

Email Details